Reclaiming the Road to Success

Full-Depth Road Reclamation Made Even Better

Full-depth reclamation (FDR) is a proven method for rebuilding deteriorated asphalt roads using liquid calcium chloride such as LIQUIDOW® as a base stabilization agent. It helps to produce a strong road base, lower material costs and eliminate the need for disposal of old pavement. As good as the traditional FDR process using LIQUIDOW is, Recon Construction Services, Inc. of York, Pennsylvania found a way to make it even better. Whichever FDR method you choose, you can be assured of “quality results at substantially lower costs and considerably shorter construction periods than conventional reconstruction practices,” per the Asphalt Recycling & Reclaiming Association (1).

How Full-Depth Reclamation Makes Roads Better

The FDR process combines the old asphalt surface materials with the underlying base to produce a rejuvenated road base that is stronger than new, virgin aggregate. The process is performed entirely on site, so the cost of removing, hauling away, and disposing of the old pavement is eliminated. Many roads require additional aggregate base material when they are rebuilt, but FDR utilizes less of this material since the old surface materials are combined with the existing aggregate. The structural integrity of the road base is increased when liquid calcium chloride is used as a stabilization agent with FDR. Greater strength and density are achieved in the road base, adding years to the expected pavement life. Frost heave damage is also reduced because calcium chloride lowers the freeze point of capillary water in road base materials.

The Traditional Method

Traditional full-depth reclamation with calcium chloride consists of six primary steps:

- A reclaimer is used to pulverize the surface and road base to a specified depth.

- Calcium chloride such as LIQUIDOW® Calcium Chloride Solution is applied to the pulverized material using a truck with a spray bar, much like a dust control treatment.

- A second pass of the reclaimer thoroughly mixes the calcium chloride with the road materials.

- The road is graded and shaped.

- Asphalt is rolled and compacted with a vibratory roller.

- Calcium chloride is applied as a top dressing or fog seal.

The Improved Three-Step Method

Recon's improved FDR technique combines the first three steps of the traditional method (pulverization, liquid application and mixing) into one step.

- Using a specially modified reclaimer, LIQUIDOW® is applied directly to the road material as it is reclaimed. Because the liquid is uniformly mixed during pulverization, the need for a second pass by the reclaimer is eliminated. Application rate is precisely controlled relative to ground speed and the reclaiming depth to assure consistent coverage of the stabilizing agent.

- The road is graded and shaped.

- Asphalt is rolled and compacted with a vibratory roller.

After shaping and compaction, the fog seal may be considered optional, depending on job specifications. The result is a densely compacted road base with consistent and uniform strength, achieved with less time and effort than was previously possible with the traditional procedure.

Proven Results

Recon has been using the improved FDR technique for many years, and they have been extremely satisfied with the results.

"I'm convinced that injecting the calcium chloride into the material as it's being processed is the key to the results we've obtained with this modified process, especially when you're talking about compaction," says Wayne Cleaver, Recon VP of Business Development, "If all your material is coated with the product, you're going to achieve better compaction than you would if the coating was only applied to the surface area."

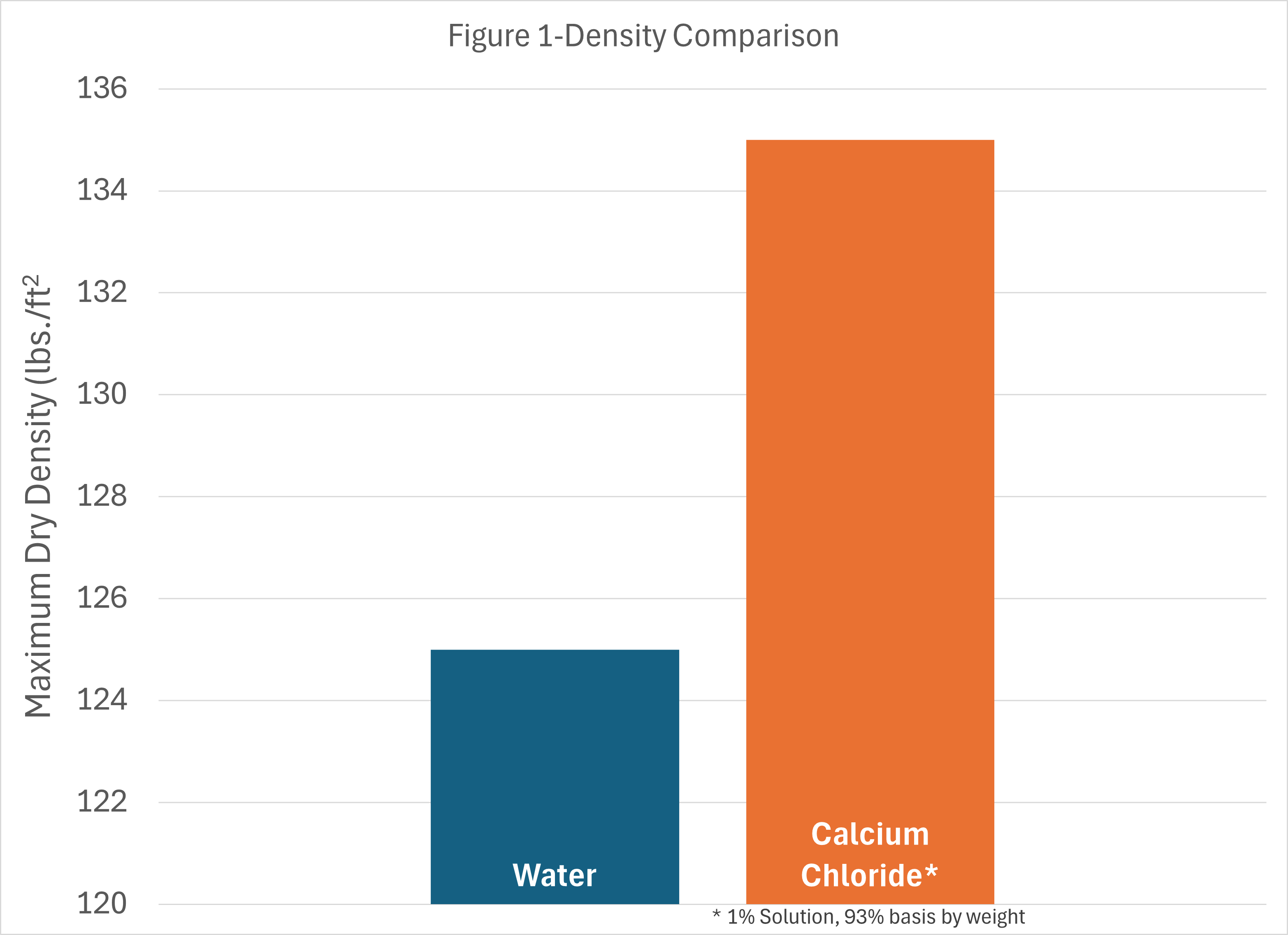

Mr. Cleaver's observations are consistent with the known physical properties of calcium chloride, which result in solutions that have a stronger moisture film than plain water. This enhances the lubrication effect produced by the liquid and allows the aggregate components to slide more easily against one another during compaction, resulting in a stronger, more compact base (Figure 1). Calcium chloride solutions also strongly resist evaporation, maintaining optimum moisture content in the road base and virtually eliminating dust problems. The potential for surface deterioration during staged construction is minimized or eliminated, so the stabilized road can be kept open for local traffic prior to final paving.

"With calcium chloride, the longer a roadbed lays, the stronger and more stable it becomes," Cleaver explains. "Prior to using FDR, a loss of surface moisture would often lead to raveling and deterioration of the road base before paving."

FDR has been a technique primarily used on rural roads, but it's increasingly becoming the option of choice in urban reconstruction projects as well. In recent years, Recon has successfully utilized the modified FDR technique in a wide range of reconstruction projects in Maryland and Pennsylvania.

"Not all of our jobs are done using modified FDR, but it's definitely the way to go if the necessary funding is available," says Cleaver. "The municipalities that have been willing to try the technique have continued to use it once they see the results."

Follow the Road to Success

Full-depth reclamation using LIQUIDOW yields a densely compacted road base with consistent and uniform strength—all at a substantially lower cost and in less time. Find your LIQUIDOW distributor and get ready to put calcium chloride and the FDR process to work for you.

1Asphalt Recycling & Reclaiming Association. Full Depth Reclamation - A Century of Advancement for the New Millennium, Annapolis, Maryland: ARRA, January 2001.