Concrete Made Better

Calcium Chloride Reduces Cement Set Time and Improves Strength

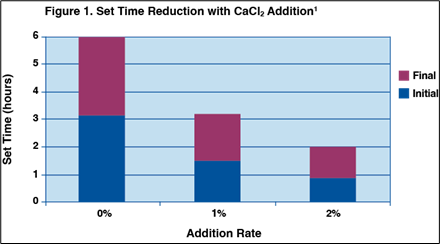

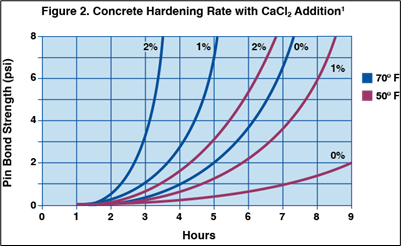

It is no surprise that calcium chloride is the most preferred additive for accelerating cement hydration. Calcium chloride reduces set time, particularly in colder weather, enabling jobs to be completed as quickly and economically as possible. In fact, calcium chloride has the ability to accelerate cement hydration and reduce set time by as much as two-thirds (see figures 1 and 2). Calcium chloride is classified as a Type C accelerating chemical admixture for concrete by ASTM C494.

What’s more, research has shown that concrete produced with 2% calcium chloride exhibits equivalent cure strength at 50°F as plain concrete at 70°F. Set times below 50°F will be longer, but the accelerated cure rate will still be greater than that of plain concrete. Calcium chloride can also improve mix workability, improve the strength of air-entrained concrete, and reduce bleeding by enabling earlier final finishing.

To sum it up, calcium chloride:

- contributes to protection against freezing when making concrete.

- increases the strength of concrete in less time.

- improves workability, since less water is required to produce a given slump.

- improves the strength of air-entrained concrete.

- allows for earlier final finishing by reducing bleeding, due to the early stiffening produced by acceleration.

How to Use Calcium Chloride in Concrete

Calcium chloride used as an admixture for concrete should meet the requirements of ASTM D98. Use our calculator for making solutions from dry calcium chloride for help. Safety and disposal precautions are listed in Safety Data Sheets (SDS) for Anhydrous Calcium Chloride 94-97% Mini-Pellets, DOWFLAKE® Xtra 83-87% Calcium Chloride Flakes and LIQUIDOW® Technical Grade Calcium Chloride Solution.

Follow these guidelines for using calcium chloride in concrete:

- The amount of calcium chloride used should not exceed 2% and should never exceed 4% due to flash set probability. Preferably, calcium chloride should be added in solution form to the aggregates in the mixer drum or as a portion of the mixing water, reducing the total mixing water required by the amount of solution being used. Use the calculator to make your solution.

- When ready-mixed concrete is used, calcium chloride should be added at the plant site if the concrete is to be discharged within one hour after the start of mixing. Otherwise, it should be added at the job site, mixing for at least three minutes or at 30 revolutions of the mixer, whichever is longer.

- If dry calcium chloride is used, it should be added free of lumps to the aggregates in the mixer drum during mixing, or to the mixed concrete just before discharge. Concentrated calcium chloride should not come into direct contact with dry cement as it may cause flash set.

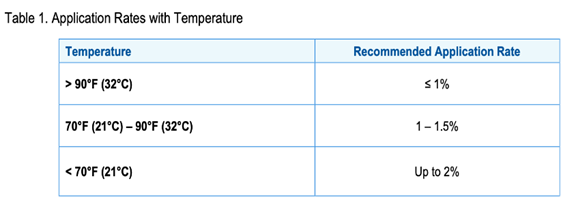

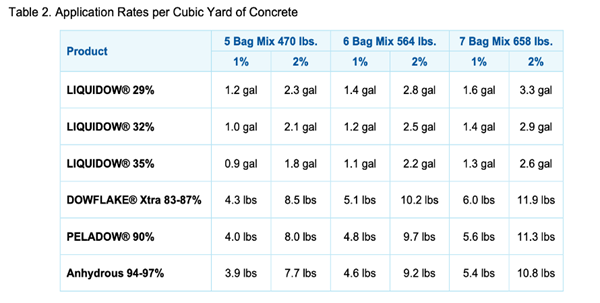

- For best results, calcium chloride application rates should vary with temperature. Table 1 contains recommendations for how to vary calcium chloride application rates with temperature, and Table 2 contains application rate guidance for 1% and 2% per cubic yard of concrete.

- If corrosion of embedded metals is a concern, it is recommended that the relevant American Concrete Institute committees be consulted for guidance on calcium chloride use under various exposure conditions.

Produce Strong Concrete, Faster with Calcium Chloride

The bottom line? Calcium chloride produces better quality concrete faster. Discover how quickly and economically you can get jobs done with help from calcium chloride’s concrete acceleration properties.

Recommended products

Anhydrous Calcium Chloride 94-97% Mini-Pellets

DOWFLAKE® Xtra 83-87% Calcium Chloride Flakes

LIQUIDOW® Technical Grade Calcium Chloride Solution

Sources of additional information:

The bottom line? Calcium chloride produces better quality concrete faster. Discover how quickly and economically you can get jobs done with help from calcium chloride’s concrete acceleration properties.

American Concrete Institute; ph: 248-848-3700; www.aci-int.org

Portland Cement Association; ph: 847-966-6200; www.cement.org

National Ready Mix Concrete Association; ph: 301-587-1400; www.nrmca.org

1 “Effect of Calcium Chloride on Portland Cements and Concretes.” Paul Rapp, Proceedings, Fourteenth Annual Meeting, Highway Research Board, (1934)

2 “Measuring the Rate of Hardening of Concrete by Bond Pullout Pins.” T.M. Kelly and D.E. Bryant, Proceedings, ASTM, Volume 57, (1957)